Diagram Fluidized Bed Combustion Boiler

Fluidized bed combustion fbc is a combustion technology used to burn solid fuels.

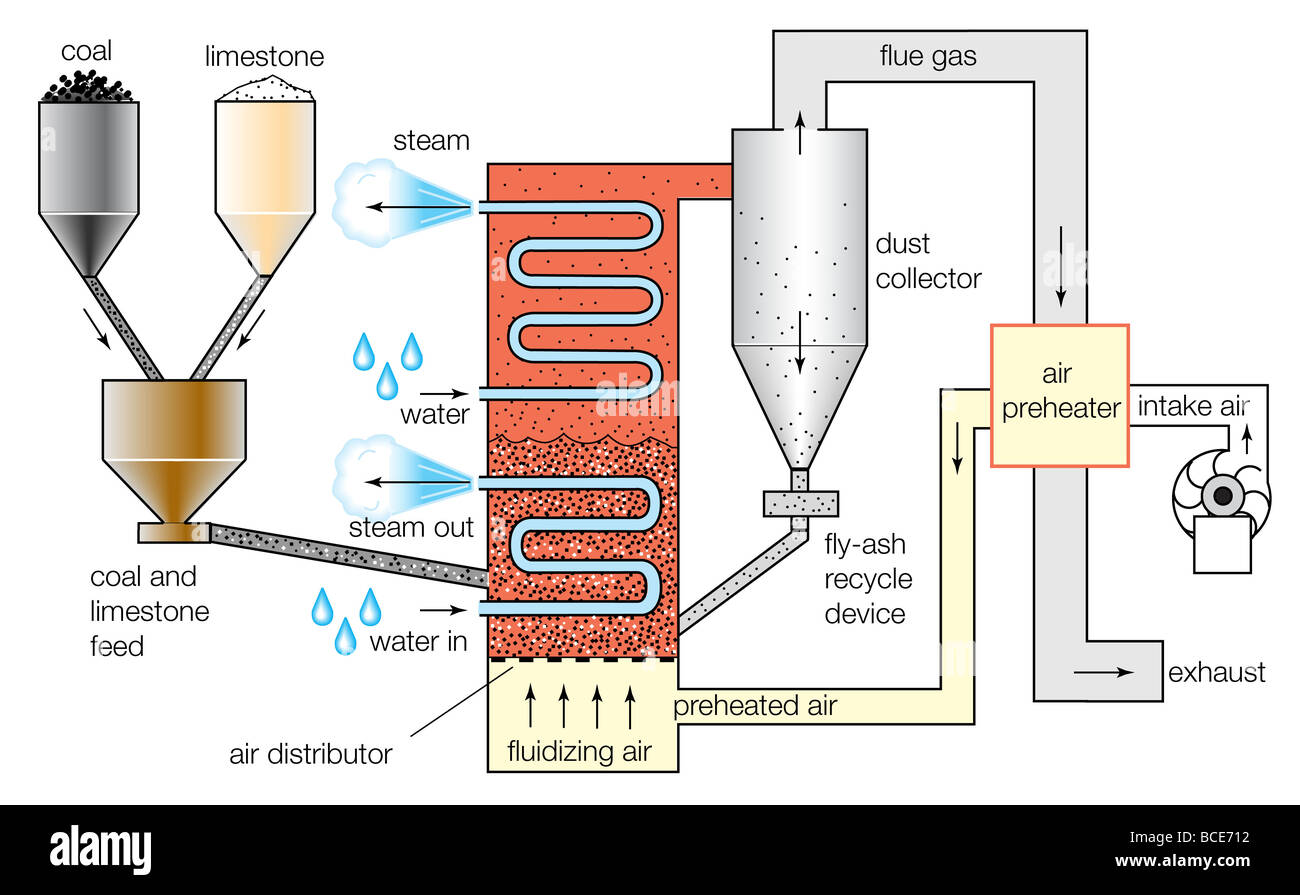

Diagram fluidized bed combustion boiler. In fluidized bed combustion a bed of crushed solid particles usually six millimetres or less is made to behave like a fluid by an airstream passing from the bottom of the bed at sufficient velocity to suspend the material in it. Fluidized bed combustion is not an so 2 control technology per se. The cfb boiler is a device that burns solid fuel to produce steam or hot water and the boiler furnace works with special fluid dynamic characteristics. Fluidized bed combustion and the role of sorbents in controlling so 2.

Coal of size 0 10mmis spread over bed typically 1 6 mm size for under bed firing and 6 10mm for overbed firing. Fbc fluidized bed combustion is a combustion technology used to burn solid fuels in steam boilers in fluidized bed combustion boiler technology when air or gas is passed through an inert bed of solid particles such as sand supported on a fine mesh or grid the air initially will seek a path of least resistance and pass upward through the sand. Introduction to fbcs 2. Bed is where the coal or fuel spreads.

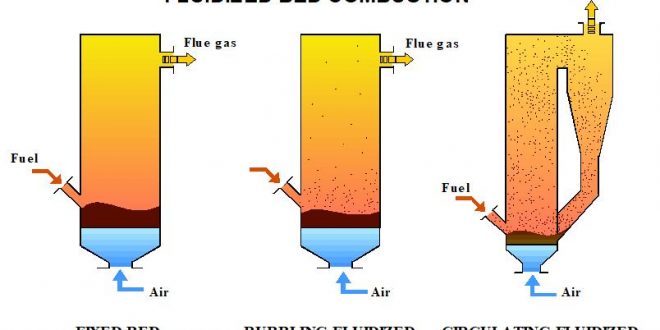

Bubbling of sand bed is created with the help of fluidizing air of velocity 1 2 3 7 m sec. Other articles where fluidized bed combustion is discussed. Fluidised bed combustion fbc burning of pulverised coal has some problems such as particle size of coal used in pulverized firing is limited to 70 100 microns the pulverised fuel fired furnaces designed to burn a particular cannot be used other type of coal with same efficiency the generation of high temp. A fluidized bed may be defined as the bed of solid particles behaving as a fluid it operates on the principal that when an evenly distributed air is passed upward through a finely divided bed of solid particles at low velocity the particles remain undisturbed but if the velocity of air flow is.

Miller in coal energy systems 2005. In this article we will discuss about 1. However this combustion technology does offer the capability to control so 2 emissions during the combustion process rather than after combustion where fgd systems need to be installed. About 1650 deg c in the furnace creates number of problems like slag formation on.

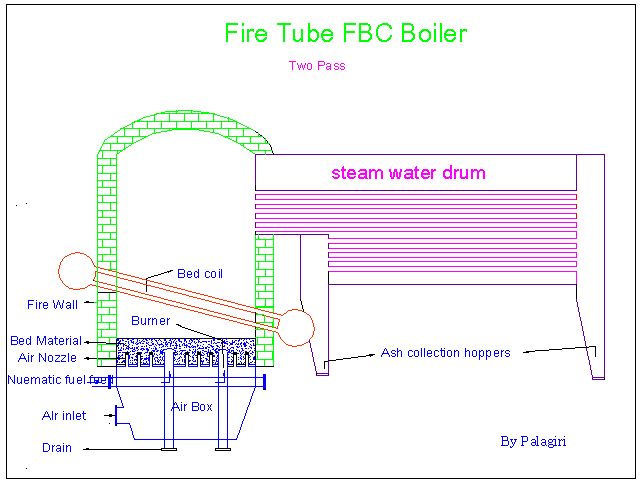

All this without compromising efficiency and with reduced emissions. In its most basic form fuel particles are suspended in a hot bubbling fluidity bed of ash and other particulate materials sand limestone etc through which jets of air are blown to provide the oxygen required for combustion or gasification. Introduction to fbcs principle of working of fluidised bed combustion types of fbc systems pressurized bubbling fluidized bed boiler pbfb advantages of fbc. Atmospheric fluidized bed boilers are most common and simple fbc boiler where combustion takes place at layer of sand or sand like material.

At the bottom of the boiler furnace there is a bed of inert material. Principle of working of fluidised bed combustion 3. Circulating fluidized bed cfb combustion boilers gives the flexibility for combustion of a wide range of coals and alternative fuel sources. Pressurized bubbling fluidized bed boiler pbfb 5.